- 417-551-4396

- info@truewatermark.com

- Mon - Fri: 8:00 - 5:00

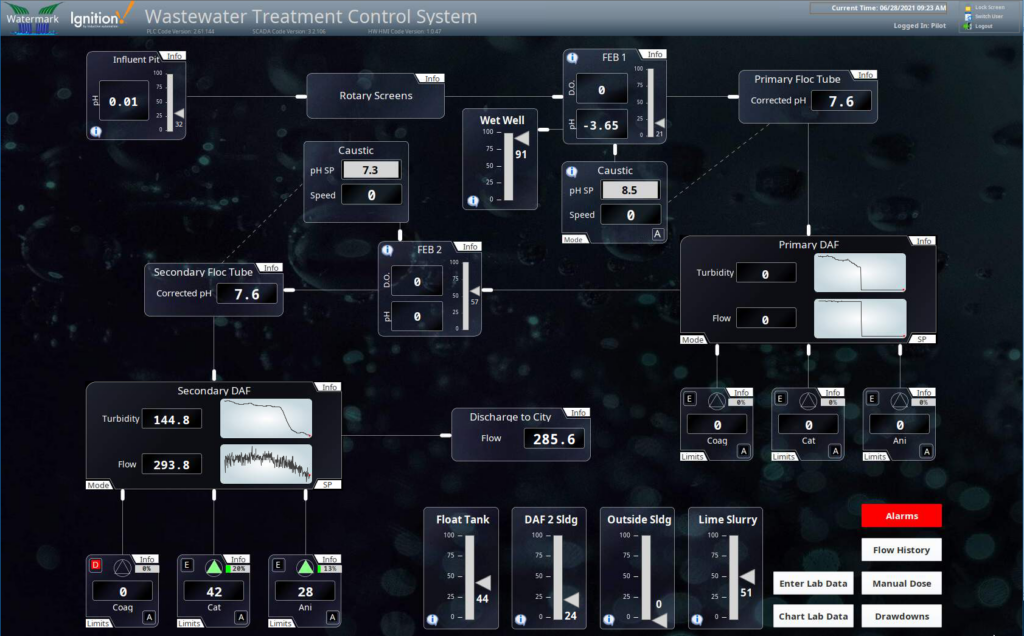

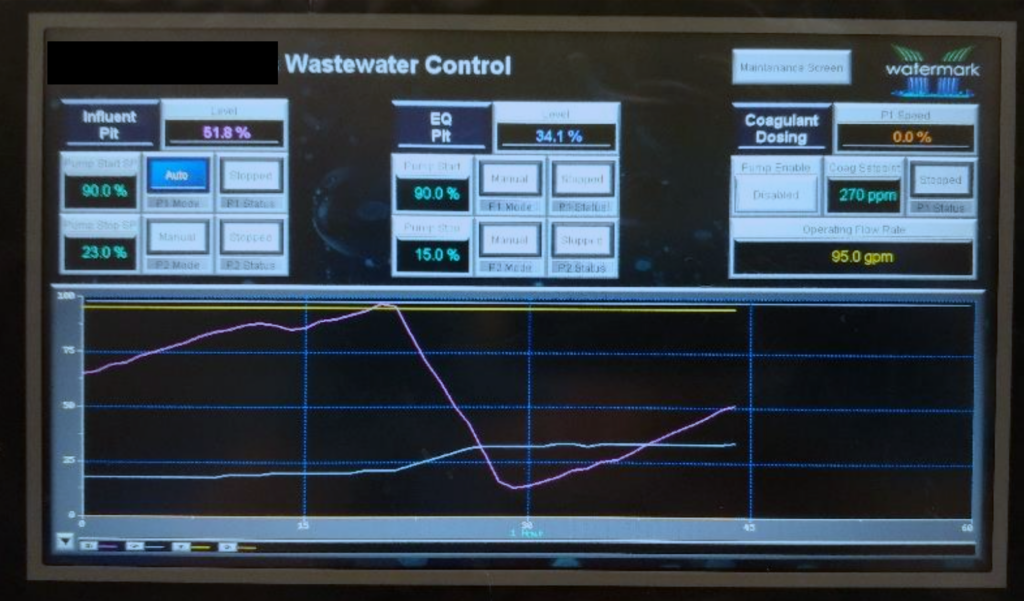

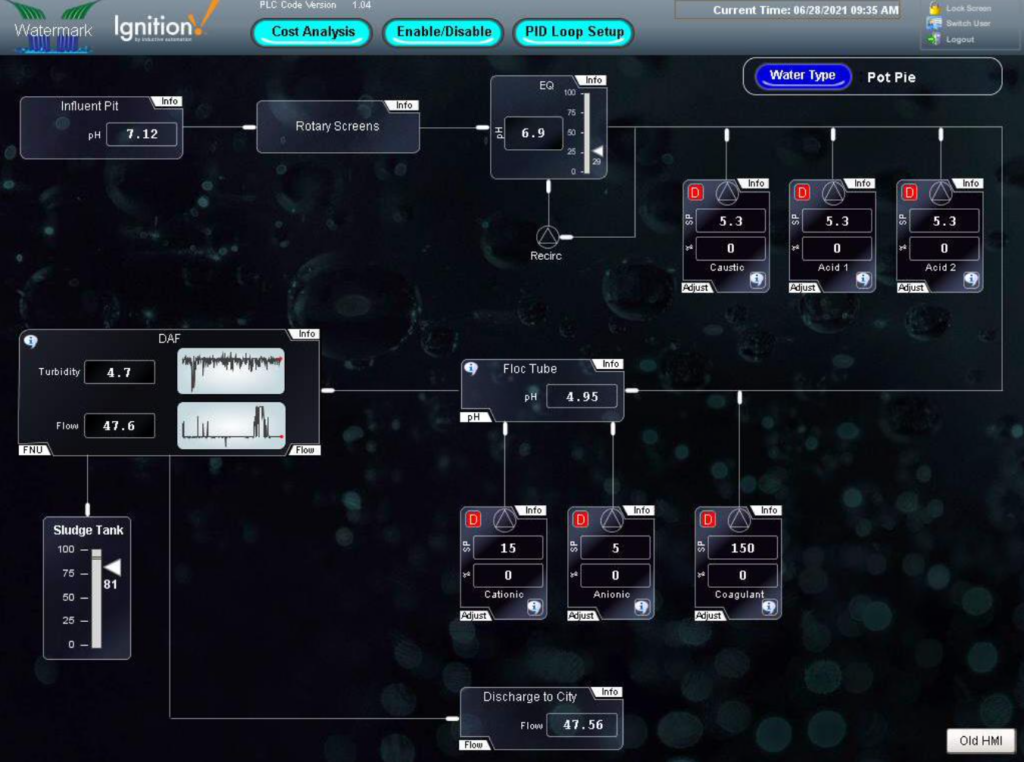

If operators are having to go to multiple pieces of equipment to start, stop or adjust processes, we can help. By providing centralized stations that allow for control of scattered equipment, we can reduce the “running around” and associated slip/fall risks while simplifying system operation.

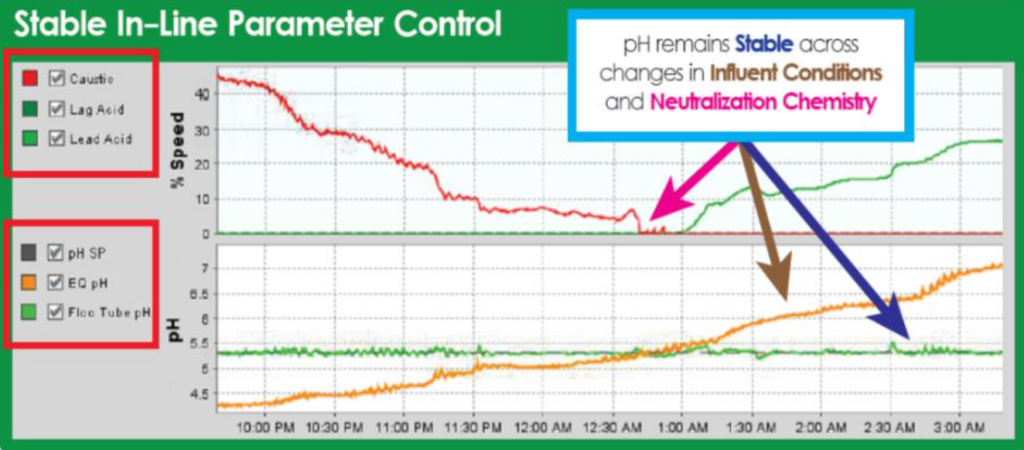

At many facilities, we find that operators are making adjustments to chemical pump speeds, transfer pump speeds, flow control valves, etc. Our automation solutions allow the operator to select setpoints for process variables such as pH, flow rate, chemistry dosing (as parts-per-million), etc., and the control system then makes the necessary adjustments to meet those setpoints. This is a much

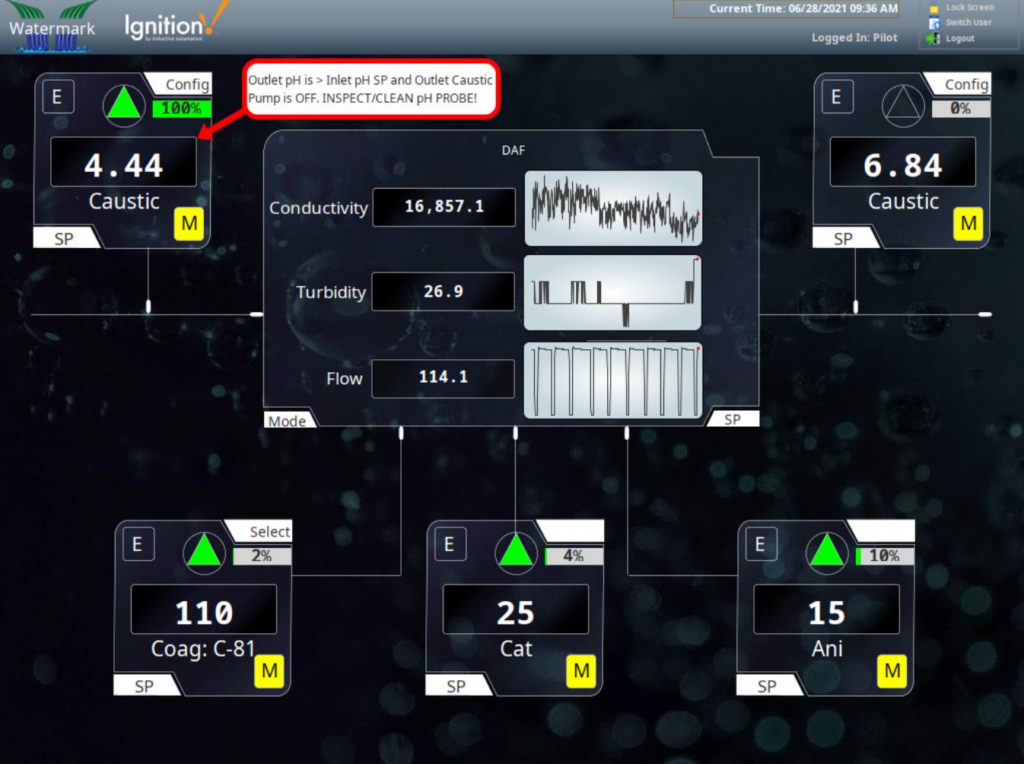

The flexible nature of our automation packages allows us to work with your operators to define alerts and alarms that can most effectively help them manage the processes the are responsible for. Infrequent events or events that can be identified only by looking at multiple variables can be very difficult for operators to identify. However, if the identifying factors can be defined and sensors exist to provide status information, we can provide notifications immediately when such events occur.

Improved Process Visibility

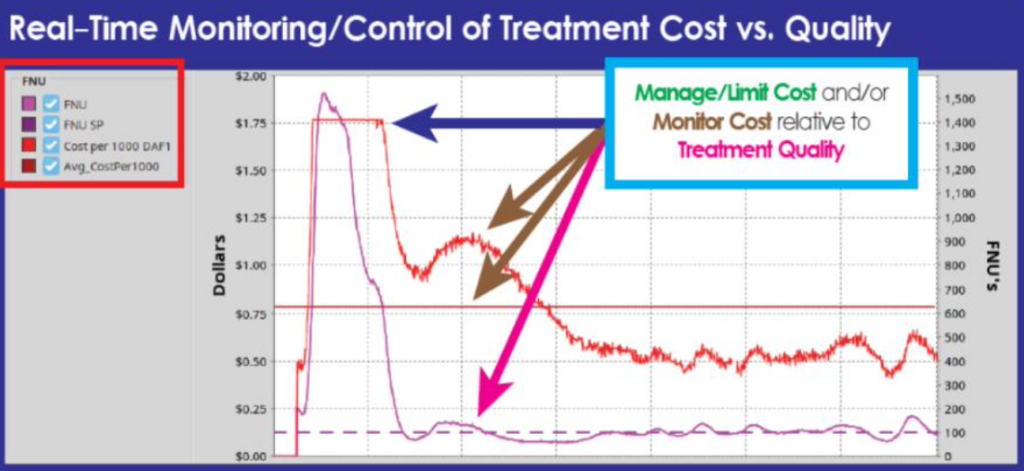

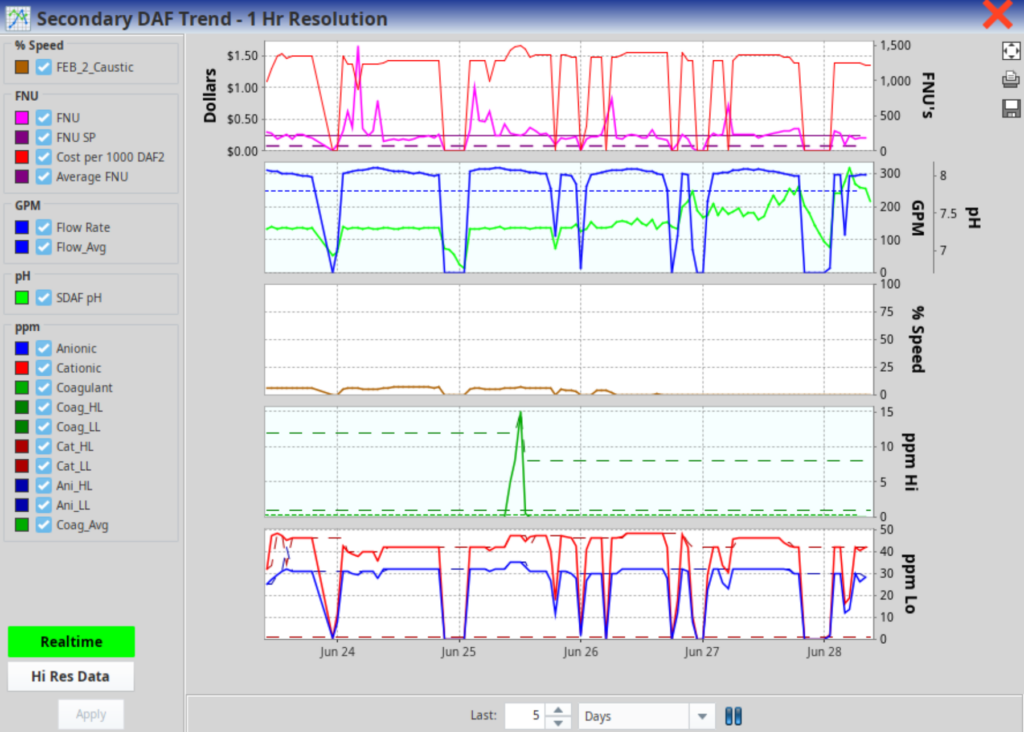

See costs in Real-Time

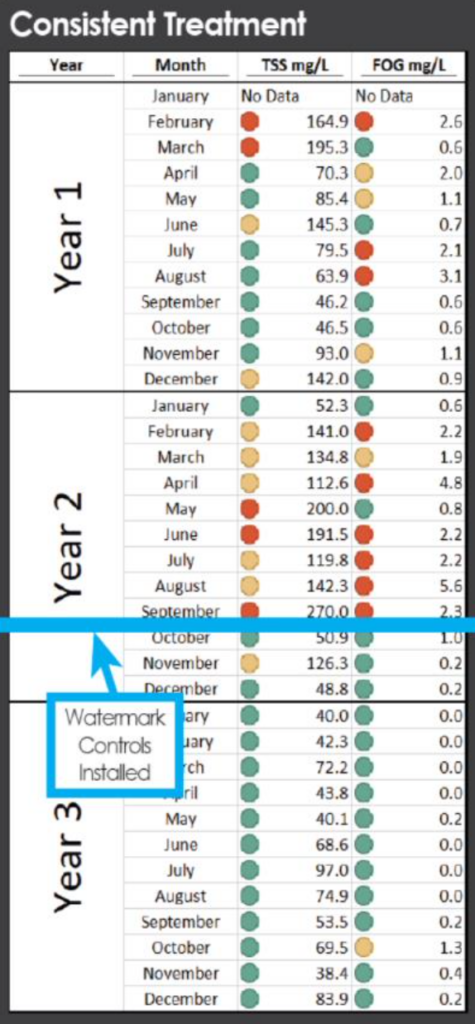

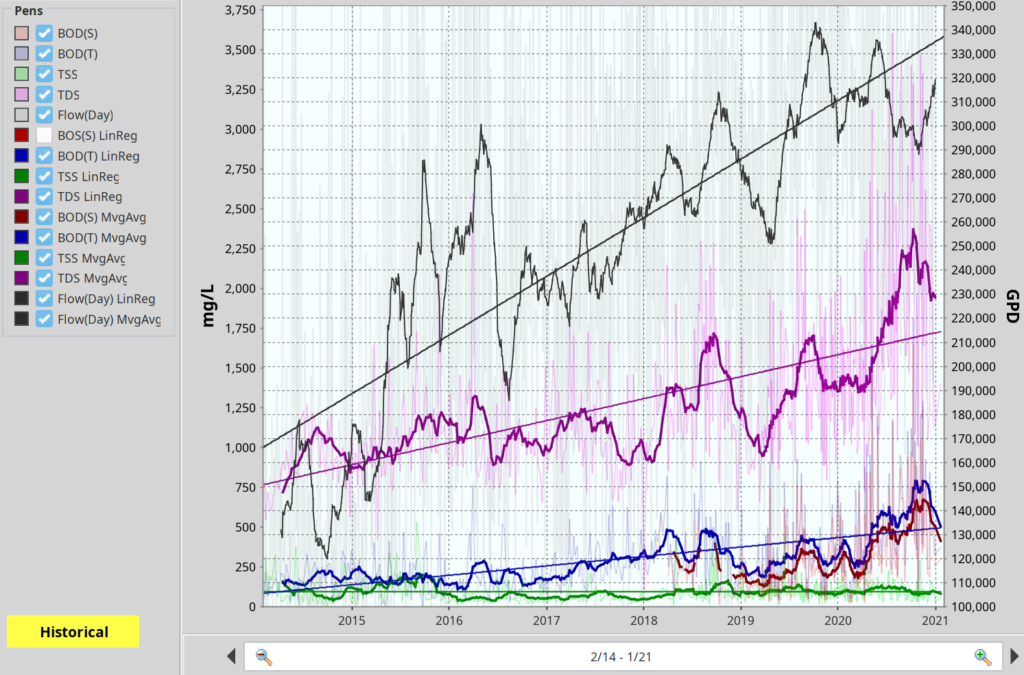

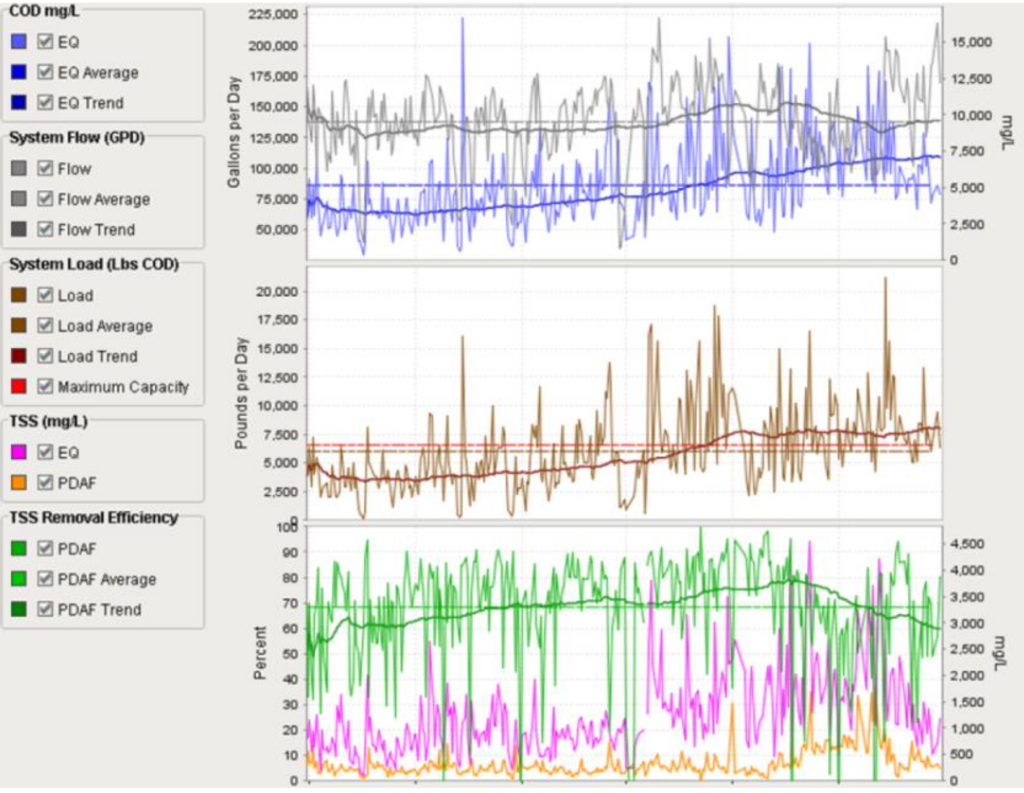

Real-Time and Long-Term (multi-year) Trends

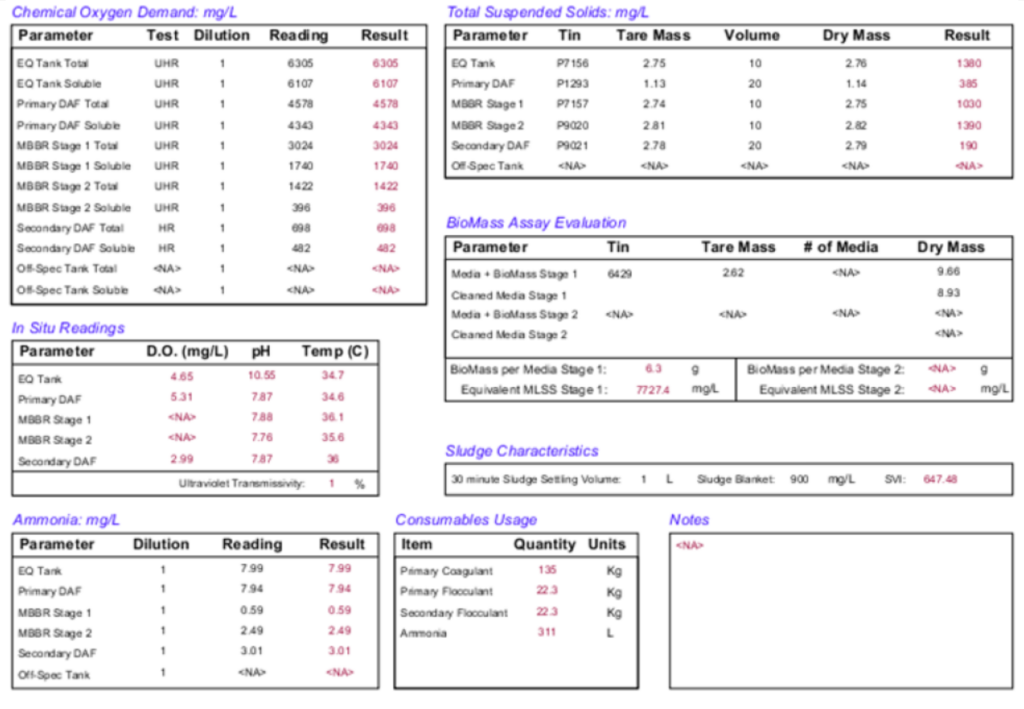

View Time-synced Real-Time and Manually Entered Data together

Actionable Data for Future Planning

Automation leads to process repeatability. Additionally, when the operators have the necessary tools to review historical information presented in a meaningful way, they are more often able to reproduce past successes.

A portable high pressure ozone solution for rinsing/sanitizing surfaces and drains.

Ozone/oxygen-based sanitation options are faster and more effective against pathogens like listeria and e coli without harming the WW biology.

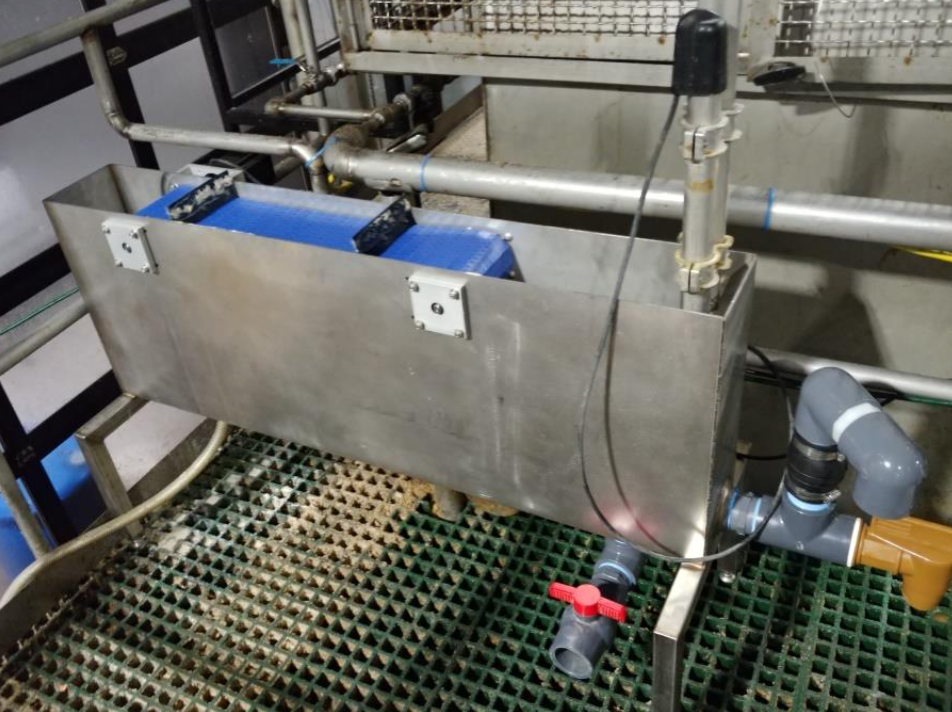

A portable, tiny DAF that can be used to enhance treatment in large-volume solids-separation systems by reducing the lag between the time chemistry/dosing updates are introduced and the results can be seen by the relevant monitoring sensor(s).

Long update/results lags make automated control very difficult, if not impossible. In on-site tests, the MicroDAF has reduced the lag time from more than an hour to less than five minutes.

Utilizes pre-dissolved gasses at high concentration to mix into low concentration liquids eliminating wasted off-0gas

For oxygenation, especially for shallow tanks/ponds/MBBRs.

For pH suppression, especially for highly alkaline streams.

Safer and more efficient than sulfuric when appropriately applied. pH streams of 9-13 can be reduced to 6 s.u. in a single pass at almost 100% efficiency

Extreme efficiency of oxygen transfer regardless of temperature and tank depth. Overcomes poor oxygen transfer efficiency. This system has demonstrated significant electrical savings for aeration. Of the existing similar technologies, the Watermark DOSat system is the least expensive while maintaining expected high performance.

Enter your email to stay in touch with us.