- 417-551-4396

- info@truewatermark.com

- Mon - Fri: 8:00 - 5:00

Generally Regarded As Safe” chemistries, tested and selected to generate an additional revenue source or minimize solids disposal costs.

Generate the least amount of solids

Maximize pre-treatment BOD reduction

Automatically adjust pretreatment dosage as the influent water changes

Minimize chemical usage. Utilize a potential revenue stream.

In-house blending of products to meet your specific requirements.

Custom chemistries from multiple suppliers to ensure the most effective treatment solution

Depending on differences between daily influent characteristics, multiple days of testing may be required.

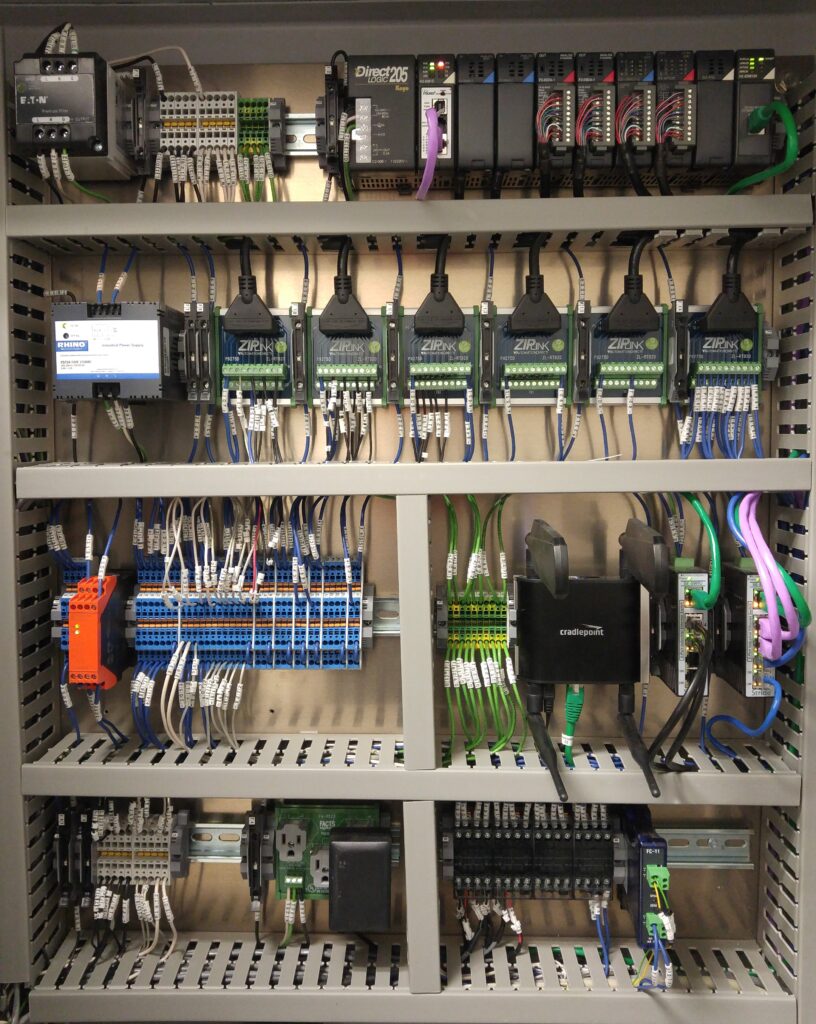

Wastewater treatment plants represent complex process trains with many input and control parameters. Our automation packages can make the variables visible in a single location and provide context by allowing disparate systems to be compared in real time or extended time periods, up to years.

Once the variables that make up a process train can be evaluated, it is possible to define operational targets. Controlling outputs to achieve these targets is where automation excels because it doesn’t get distracted, bored, called away to meetings, sick, etc. Its behavior is predictable and reliable, 24 hours a day, 365 days per year.

Once a properly designed automation system is in place, chaos recedes. The operator’s scope of work shrinks from constantly having to check inputs and adjust outputs to simply defining the goals/targets/setpoints that the automation should achieve. Additionally, the operator decisions are logged and can be easily viewed alongside the real-time system performance data. This makes it much easier to determine if an operator is making appropriate decisions regarding treatment processes and generates a documentation trail to support personnel management decisions.

Personnel are expensive; competent, qualified personnel much more so. Without automation, the experience and skill that these individuals have are often wasted as they are forced to constantly make minute decisions that could be easily achieved by a simple algorithm. Our solutions free the operator from mundane, repetitive tasks, opening up the time for them to make informed process management decisions, perform preventive maintenance activities, gain additional training, etc.

Minimize chemical usage. Utilize a potential revenue stream.

-No capital expense

-Odor control that actually works to make your process invisible to the nose

-New, proprietary technology

-Reasonably priced and actually provides the results you thought you were paying for

-Fixed cost makes for easy budgeting

We utilize a proprietary chemical formula and technique that is so fast that in most cases the odor is destroyed even before it enters the air scrubber.

That leaves the scrubber to work on a tiny amount of odor and primarily as a polisher.

The technology produces in pipe instantaneous reactions and has proven successful in one location without an air scrubber at all. Just the exhaust stack.

Our fixed cost for this system (including required chemical) is most often less then your current budget with far superior results and service.

We can provide pH control for your application.

Downward pH correction using CO2 gas infusion

CO2 Gas Infusion; Avoid issues commonly associated with using acid – safety, H2S/corrosion (if sulfuric), secondary treatment complications, etc.

We can supply the material that fits your application best

This technology is automated and performs with extreme efficiency.

The saturated stream is then mixed with the low DO stream with no appreciable off gassing even in a shallow flow.

The DOSAT technology can be utilized very cost effectively on LOX, as well as on-site generated oxygen supplies.

There are only a few oxygen transfer technologies this efficient and DOSAT will likely prove the most affordable and with the most intuitive automation. Oxygen is tightly controlled, and it is doubtful that any would be wasted to atmosphere unless the entire body of water is saturated.

Consider requesting a quotation today.

Enter your email to stay in touch with us.